Unlock the Future of Industrial AI! Discover how OPX Ai’s advanced solutions can optimize operations, reduce emissions, and drive profitability.

AI-Driven Efficiency

With OPX Ai, you get proven AI-driven solutions that deliver real results—not just more data.

📈 Our Solutions Have Helped Leaders Achieve:

✅ 30% Faster Decision-Making with AI-powered Integrated Operating Centers

✅ 5-30% Downtime Reduction through Predictive Maintenance

✅ 15-25% Higher Oil Recovery with Artificial Lift Optimization

✅ 20-80% Reduction in Methane Emissions for ESG & Regulatory Compliance

✅ 20% Energy Efficiency Gains with Digital Twin Technology

✅ Real-Time Hydrate Detection to Prevent Flow Blockages

💡 Take Control of Your Operations – Talk to Our SMEs Today!

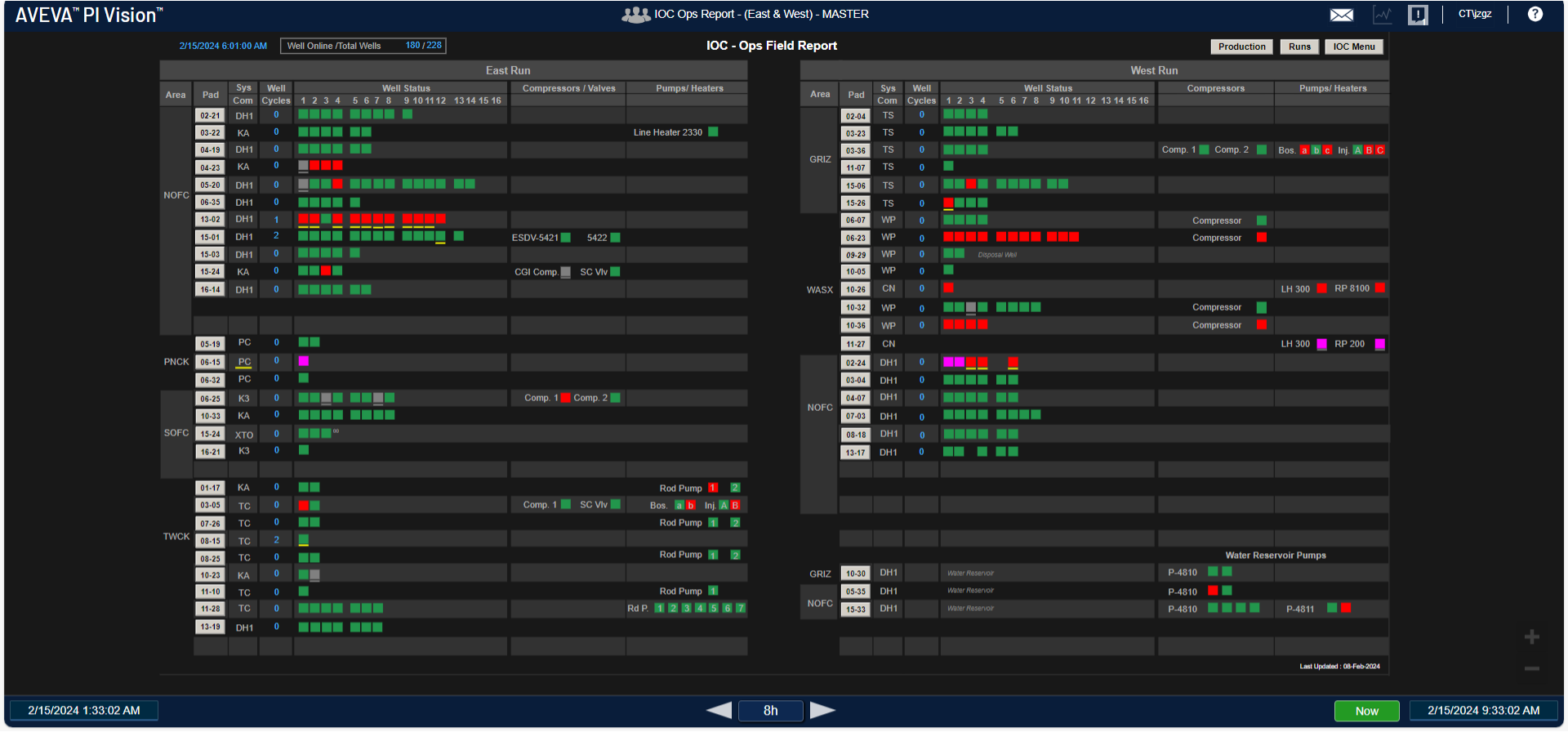

Integrated Operating Centers (IOC)

📌 Make Real-Time, Data-Driven Decisions from Anywhere

What We Deliver:

✔ Centralized, AI-powered remote operations

✔ Anomaly detection for real-time issue resolution

✔ SCADA & PI System integration for full visibility

✔ Automated workflows to reduce manual intervention

📈 Key Results for Oil & Gas Operators:

🔹 50% faster response times to production issues

🔹 30% workforce productivity boost with streamlined processes

🔹 Fewer unplanned shutdowns, saving millions in lost production

📩 → Get a Demo and See It in Action!

Artificial Lift Optimization

📌 Maximize Well Production with AI-Powered Lift Strategies

What We Deliver:

✔ AI-powered optimization for gas lift, ESP, plunger lift & rod pumps

✔ Real-time data analysis to dynamically adjust lift parameters

✔ Predictive maintenance to reduce pump failures

✔ Integration with SCADA & PI System for continuous monitoring

📈 Key Results for Oil & Gas Operators:

🔹 15-25% increase in oil recovery per well

🔹 Lower energy consumption with optimized lift parameters

🔹 Up to 30% reduction in well maintenance costs

📩 → Increase Well Productivity – Let’s Discuss Your Lift Strategy!

AI-Powered Asset Optimization

📌 Prevent Equipment Failures & Extend Asset Life

What We Deliver:

✔ AI-driven predictive failure detection for pumps, compressors & pipelines

✔ Real-time monitoring via SCADA & IoT sensors

✔ Automated maintenance scheduling to cut downtime

✔ Root cause analysis to improve asset reliability

📈 Key Results for Oil & Gas Operators:

🔹 40% drop in maintenance costs with predictive insights

🔹 20% increase in equipment lifespan

🔹 Up to 97% accuracy in failure forecasting

📩 → Start Predicting Failures Instead of Reacting to Them – Talk to Us!

PI & SCADA Optimization

📌 Faster, Smarter, AI-Powered SCADA & Control Systems

What We Deliver:

✔ Custom SCADA dashboards for enhanced visibility & control

✔ AI-driven automation to reduce operator workload

✔ Real-time alerts & anomaly detection for proactive responses

✔ Integration with existing DCS, PLC, and industrial networks

📈 Key Results for Operators:

🔹 50% improvement in operator efficiency

🔹 30% increase in uptime with AI-driven monitoring

🔹 Reduced response times, cutting safety risks & production losses

📩 → Supercharge Your SCADA System – Let’s Get Started!

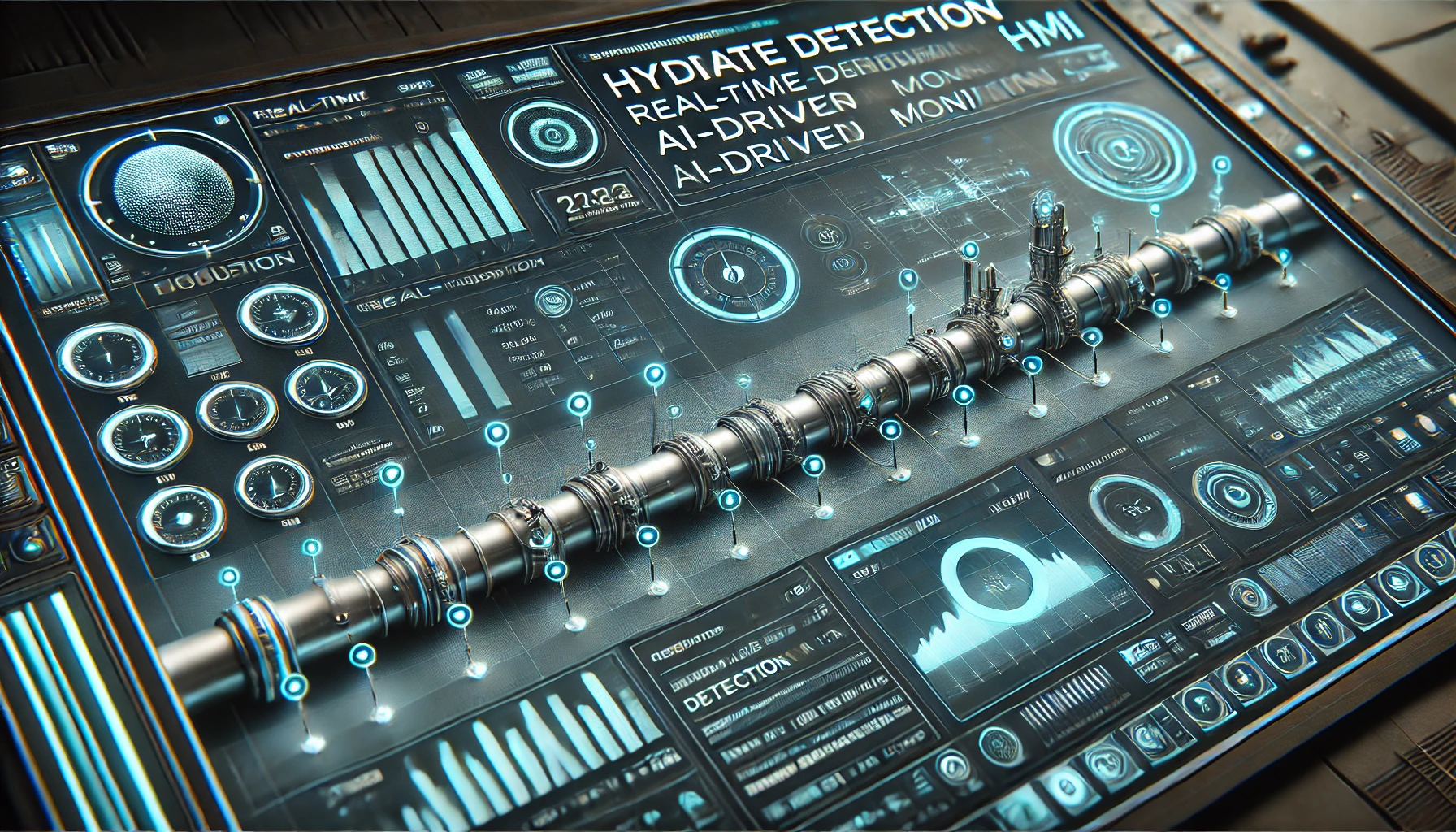

Ai & Hydrate Detection

📌 Prevent Hydrate Formation & Flow Blockages in Pipelines

✔ AI-driven hydrate detection in real-time

✔ Flow assurance analytics for pipeline integrity

✔ Predictive modeling for early intervention

✔ SCADA & IoT integration for continuous monitoring

📈 Key Results:

🔹 Prevent pipeline blockages & unplanned shutdowns

🔹 Reduce chemical injection costs by up to 20%

🔹 Ensure continuous, optimized production flow

📩 → Stop Hydrates Before They Disrupt Operations – Let’s Talk!

Why Managers Choose OPX Ai?

✅ We Know Oil & Gas – Decades of experience in upstream & midstream operations

✅ AI That Works – Proven results in production optimization & emissions reduction

✅ No More Guesswork – AI-powered analytics for real-time, data-driven decisions

✅ End-to-End Support – From system integration to full-scale deployment

🚀 It’s Time to Stop Reacting and Start Predicting with AI!

📩 → Contact OPX Ai Today for a Free Consultation!